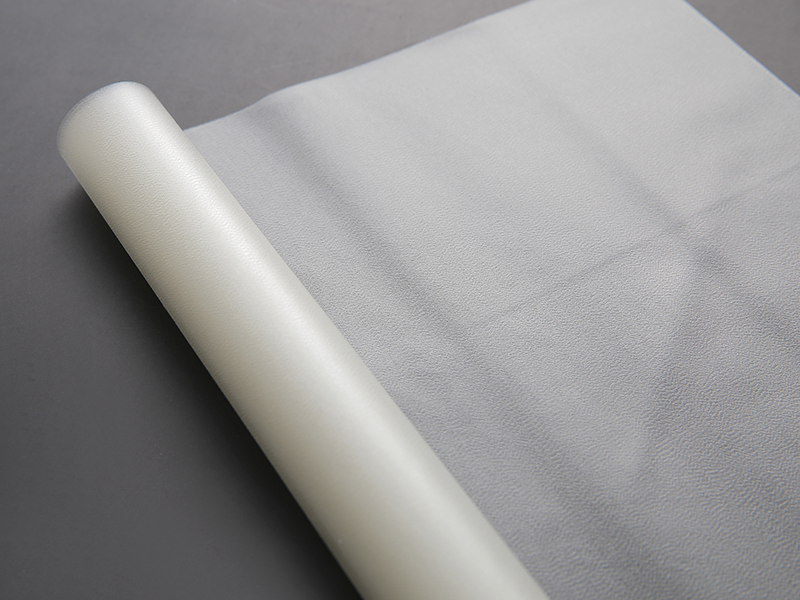

Ionic Intermediate Membrane

Manufacture: Automotive Grade PVB Flim、Architectural Grade PVB Flim. Especially In Colour PVB Flim Manufacturing Is The Most Professional.

The ionic interlayer film has high bonding properties, optical properties, and mechanical properties, which can fully meet the needs of the laminated safety glass industry for interlayer films. Compared with PVB membrane, ionic polymer membrane laminated glass has the following characteristics:

Product performance

| Comparison of physical parameters of interlayer film | |||

|

project |

Ionic intermediate membrane |

PVB film |

Testing standard |

|

Tensile Strength |

34Mpa |

25Mpa |

ASTM D-638 |

|

Elongation at break |

350% |

250% |

ASTM D-638 |

|

density |

0.96g/cm3 |

1.067/cm3 |

ASTM D-792 |

|

Transmittance |

89% |

89% |

JC/T2166-2013 |

|

Haze |

<1% |

<1% |

JC/T2166-2013 |

|

Yellow index |

<2 |

6-12 |

JC/T2166-2013 |

|

Moisture content |

<0.1% |

0.35%-0.55% |

JC/T2166-2013 |

|

Thermal expansion coefficient |

100x10-6mm/mm/℃ |

155x10-6mm/mm/℃ |

ASTM D-696 |

|

Heat distortion temperature |

37℃ |

--- |

ASTM D-648 |

|

Shear modulus (30℃, 3s) |

140Mpa |

1.3Mpa |

ISO-6721 |

Product specifications

|

thickness |

width |

length |

|

0.76mm |

The maximum width is 2440mm, customized according to customer needs |

200m |

|

0.89mm |

The maximum width is 2440mm, customized according to customer needs |

200m |

|

1.14mm |

The maximum width is 2440mm, customized according to customer needs |

150m |

|

1.52mm |

The maximum width is 2440mm, customized according to customer needs |

100m |

Our Products Are Mainly Used In The Field Of Digital Photography, Photographic Equipment And Other Related Industries.